Engineering Marvel: The Channel Tunnel

A Centuries-Old Dream Realized

For centuries, connecting mainland Europe to the island nation of the United Kingdom by fixed link seemed like an impossible dream. As early as 1802, engineers proposed digging a tunnel beneath the English Channel. However, opposition and technological limitations prevented progress for over a century. By the 1980s, improved tunneling methods and political will reignited the long-discussed project. After nearly a decade of construction, the Channel Tunnel officially opened in 1994, fundamentally altering transportation and connections between France and the U.K.

Careful Geological Surveys and Engineering Studies

Realizing such an ambitious underwater tunnel required extensive feasibility research. Engineers conducted careful geological surveys over 20 years to understand the sediment composition beneath the Channel. They discovered four primary layers - Grey Chalk, Chalk Marl, Glauconitic Marl, and Gault Clay. Digging in the wrong stratum risked tunnel collapse or flooding. After analysis, the Chalk Marl proved the optimal layer due to its mudstone composition.

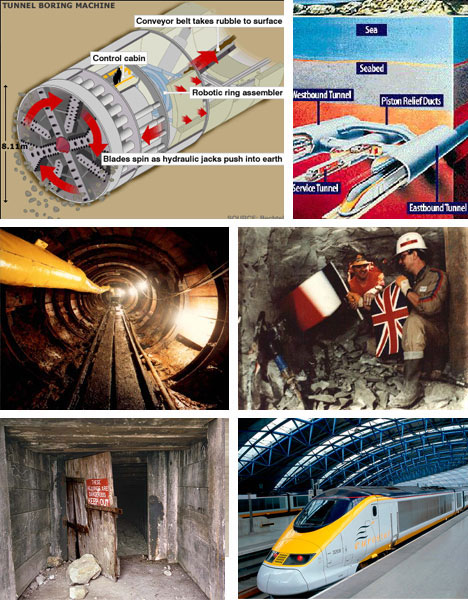

Innovative Tunnel Boring Machines Cut Through Sediment

Constructing the tunnel involved groundbreaking tunnel boring machine (TBM) technology. Powerful TBMs cut through the Chalk Marl, collecting residue and installing precast concrete lining segments to support the borehole. Engineers designed the lining segments to withstand pressures for over 120 years with minimal maintenance. Cutting through the sediment layers over 32 miles presented a massive engineering feat requiring immense coordination and planning.

A Vital Multi-Modal Transportation Link

When completed in 1994, the Channel Tunnel immediately transformed travel between the U.K. and Europe. Eurostar high-speed passenger trains connect major cities like London and Paris in just over two hours. Millions of travelers now use the tunnel each year. The tunnel also plays a vital role for freight, with over a million tonnes transported annually between markets. Its opening created a direct land connection where only ferries and air travel existed before.

Planning Complex Underground Infrastructure

Constructing the Channel Tunnel raised myriad engineering challenges that planners addressed with care and innovation. Successfully delivering such an ambitious mega-project required addressing issues like safety, logistics, environmental concerns, and complex geology. Let’s explore some of the project’s most notable planning aspects.

Ensuring Tunnel Integrity Beneath Open Waters

Boring the tunnel through sediments below the English Channel necessitated robust construction to prevent collapse or flooding. Engineers designed tunnel lining with thick precast concrete segments joined to create enduring monolith tunnel tubes. They also installed drainage and pumping systems to remove groundwater accumulating during construction and long-term use.

Coordinating Simultaneous Construction from Both Ends

To complete the project efficiently, tunnelers worked simultaneously excavating from ports in Kent, England and Nord-Pas-de-Calais, France toward the mid-channel meeting point. Coordinating two tunnel boring machine teams and supporting infrastructure over such a vast distance presented unprecedented logistical challenges. Careful scheduling and alignment ensured the segmented bores met precisely as planned.

**Implementing Strict Safety Protocols **

Given its function as a crucial transportation artery, the Channel Tunnel required robust safety systems to protect workers, equipment, and future users. Engineers developed controls for fire containment, ventilation, evacuation processes, and emergency response. Automated monitoring and incident command centers aided rapid response. Unfortunately, several worker fatalities did occur during construction, underscoring the project’s inherent risks.

**Minimizing Environmental Disturbance **

Planners sought to limit environmental impacts from the massive construction process. They utilized existing ports to access the work sites and established procedures to contain contaminants. Tunneling avoided disturbing sensitive shoreline habitats wherever possible. Post-construction, monitoring continues to help protect the fragile Channel seabed ecosystem traversing below.

Structural Engineering Innovations Enabled Success

Breaking new ground in tunneling technology, materials, and design allowed engineers to overcome the Channel’s engineering barriers. Daring ideas transformed from concepts on paper to physical infrastructure connecting nations. Let’s explore some of the structural innovations that made the ambitious tunnel project feasible.

Giant Tunnel Boring Machines Revolutionized Construction

Massive tunnel boring machines (TBMs), some 130 feet long, represented the cutting edge of tunnel construction capabilities. With computer controls and mechanical muscle, they excavated through sediment layers at rates far surpassing traditional drill-and-blast methods. Tailored cutterheads and muck removal systems optimized sediment extraction.

Durable Segmental Lining Ensured Longevity

Prefabricated concrete lining segments joined inside pre-bored pilot tunnels allowed efficient construction of robust, permanent tunnel structures. Each hexagonal or doughnut-shaped piece, some weighing over 5 tons, locked into neighboring pieces for cohesion. The segmented design simplified logistics while creating sustainable, waterproof tunnel walls.

Ingenious Undersea Links Enabled Connection

Overcoming the last seabed obstacles required novel “sumps” - junction areas near each shore designed for controlled flooding if needed. Inflatable plugs and diversion tunnels around these sumps enabled continuous construction despite tidal currents. Without such ingenuity, breaching the final sediments may have proven impossible.

Railway Systems Supported High-Capacity Transit

The twin-bore tunnels accommodate international passenger trains as well as vehicle-carrying shuttles. Precise clearances, tracks, electrified catenaries, signals, ventilation, emergency exits, and management centers supported this complex transportation function in the intense subterranean environment.

A Landmark of 20th Century Infrastructure

After a decade of herculean effort, determination and engineering prowess triumphed to complete the Channel Tunnel. Though facing immense technical and logistical barriers, thorough studies, innovative designs and workforce coordination paved the way. When open for traffic in 1994, it stood as a flagship symbol of international cooperation and human accomplishment. Today, this critical transportation artery handles over 200 million passenger journeys - a testament to the vision and skill that transformed an age-old dream into engineering reality. While continually improving safety and operations, the spectacular tunnel remains an inspiration for ambitious infrastructure projects to come.