Understanding Automotive Steering Systems

How Steering Works

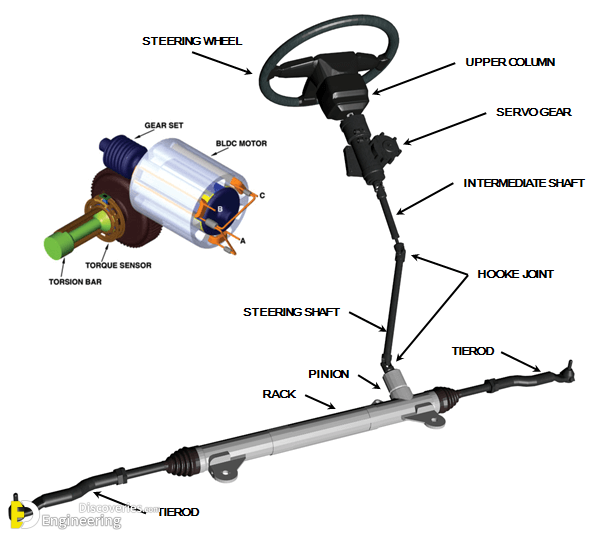

Steering systems allow drivers to control the direction of travel for their vehicles. At its most basic, steering involves changing the angle at which the front wheels point relative to the direction the vehicle is moving. By turning the steering wheel, the driver inputs a command to the steering gear which then mechanically changes the axis of the front wheels’ rotation. Early vehicles used direct linkage between the steering wheel and front axle or wheels, but modern systems almost universally employ some type of mechanical advantage system between the driver input and the wheels. This makes steering effort easier and allows for features like power assistance. The two primary types of mechanical steering gear are rack-and-pinion and recirculating-ball steering.

Rack-and-Pinion Gear

A rack-and-pinion gear system uses a toothed rack bar that runs side-to-side below the vehicle. Connected perpendicular to this rack is a pinion gear attached directly to the lower end of the steering shaft. As the driver turns the steering wheel, the pinion gear rolls sideways along the rack, changing its orientation. Tie rods connect each end of the rack to the steering knuckles of the front wheels. The linear motion of the rack translates rotational force from the wheel into changing the wheels’ axis. Rack-and-pinion gears are compact and relatively simple compared to other designs. They offer good feel and response at the steering wheel. Modern vehicles almost universally use rack-and-pinion steering for these benefits. The gear ratio between pinion and rack determines the steering effort needed and how many turns of the wheel correspond to full left-to-right travel of the wheels. Tighter ratios mean less effort but less precise control at higher speeds.

Recirculating-Ball Steering

Earlier vehicles commonly used recirculating-ball steering gear which is more mechanically complex. It employs a worm gear driven from the steering column that turns inside a nut containing balls. This motions turns a pitman arm and center link which transmits rotational force to the outer tie rods and wheels. Recirculating-ball boxes offer robustness but less feel and precision than rack-and-pinion. They have been largely replaced by the simpler rack-and-pinion except in some heavy trucks. Steering ratio is adjusted through the selection of worm and nut components to suit the vehicle’s intended use and characteristics.

Power Steering Systems

Nearly all modern vehicles incorporate power steering to make rotating the wheels easier, especially when the wheels are straight ahead. Power steering systems multiply the driver’s input force using an assist mechanism, usually hydraulic or electric. Hydraulic power steering uses a pump driven by the engine that pressurizes fluid. Force cylinders use this pressure to multiply the driver’s steering torque. Electric power steering (EPS) replaces the hydraulic components with an electric assist motor. EPS systems can vary assist based on vehicle speed for better feel and fuel efficiency. Power steering became widespread due to increased vehicle size, mass, and wider tires which require more effort to turn. It provides assistance only when steering, leaving the driver feeling fully in control. When the assist fails, manual steering is still possible, just requiring more effort. Proper maintenance helps ensure steering reliability.

Steering System Components

In addition to the steering gear and assist mechanisms, key components that transmit rotational force to the wheels include:

- Tie rods: These connect the steering gear to the steering knuckles and allow angular movement of the wheels. Inner tie rods attach to the steering box while outer tie rods mount to the knuckles.

- Pitman arm: On recirculating-ball boxes, this arm projects from the steering gear and attaches to the center link bar to transmit rotational motion.

- Idler arm: Positioned opposite the pitman arm, it supports the center link bar on recirculating-ball systems.

- Steering knuckles: Mounted to each wheel, these brackets receive the outer tie rods to change the wheels’ axis in response to steering input. Ball joints permit wheel suspension movement independently of the steering geometry.

Proper lubrication and adjustment of all steering linkage joints helps maintain reliable steering control and reduce wear. Replacing worn parts prevents dangerous steering issues from developing.

Factors Affecting Steering Feel

The number of turns lock-to-lock for the steering wheel, its position and design all impact steering road feel or how well the driver can sense the vehicle’s interaction with the road surface:

- Passenger vehicles average 2.7-3 turns lock-to-lock for easier low-speed maneuverability compared to sports cars.

- Lowering the steering column and adjusting the telescoping wheel helps drivers find a comfortable position with arms bent at 90 degrees.

- Sports car wheels have fewer turns lock-to-lock (900 degrees) for quicker response while larger trucks may reach 4 turns for effortless low-speed control.

- Steering gear ratio selection and tuning of EPS systems influence on-center feel and effort required at higher speeds where too much sensitivity could compromise stability.

With practice, a driver learns to interpret subtle steering feedback to smoothly place the vehicle where desired. Careful setup optimizes feel for different types of driving.

Suspension Effects on Steering

The vehicle’s suspension design also interacts with steering dynamics. Components like:

- Shocks/struts: Dampening controls transient wheel movements when striking bumps to maintain consistent tie rod angles.

- Sway bars: By resisting lateral body roll, they help wheel contact remain perpendicular to keep the vehicle tracking straight.

- Tire sidewall stiffness: Softer sidewalls absorb impacts better but may bounce the suspension momentarily altering steering geometry. Well-tuned suspension balance aims to optimize both ride quality and predictable steering behavior important for safety. Upgrades like anti-roll bars or stiffer springs can heighten feedback for performance driving while cushioned struts benefit daily commutes. Matching suspension to intended use optimizes overall vehicle control. In summary, reliable and predictable steering depends on many interrelated factors from mechanical linkage design to suspension tuning. Understanding how components interact helps drivers appreciate their vehicle’s handling characteristics and potential areas for improvement. With some adjustment, steering feel can often be tailored to suit an individual’s preferences and style of motoring.